IKEA

Key achievements

- 24% water use reduction

- 5 million litres saved

- 1 year pay back

Our newly appointed facility manager was concerned about excessive water use through the cooling tower.

Water treatment providers identified a faulty ball float valve in one of the cooling towers causing a continuous overflow of water to the sewer. The valve remained unrepaired for several months, causing significant damage to equipment and an estimated water loss of more than 5 million litres.

"Being vigilant and carrying out simple daily checks costs nothing but has the potential to save thousands in repairs, water and energy costs. It can also help identify improvements in operating procedures by studying cycles, occupancy, trends etc. and adjust operations to suit the variables" - Jeremy Cave, Facility Manager

Water flowing inside the cooling tower.

Taking action

A simple and cheap change saved us thousands and significantly reduced water use. We replaced the ball float valve in the cooling tower for $120.

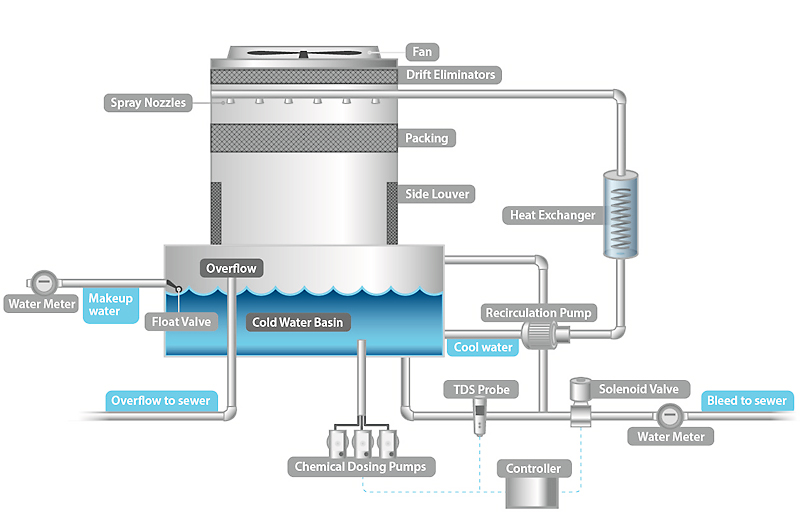

Diagram showing the location of the floating valve where the ball float was replaced.

What we’re doing now

We run the following proactive checks to stay on top of any potential issues.

- Daily maintenance check sheet carried out by staff

- Weekly checks by the facility manager

- Water Efficiency Management Plan Program participation

- Installation of water efficient appliances within the facility

- Regular meter reading and trending of water use