Grease arrestor maintenance

Grease arrestors must be maintained and regularly cleaned in order to continually operate efficiently.

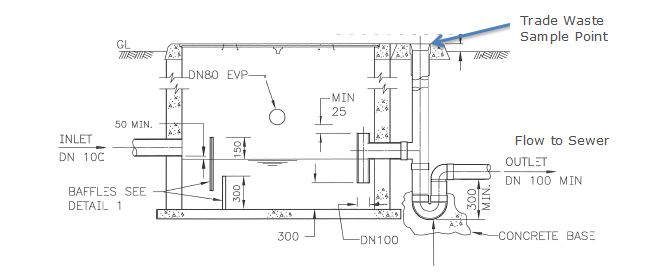

A grease arrestor or grease trap is usually a rectangular tank or pit with a baffle at the inlet end and a T-square outlet (see Figure 1). This is the most commonly used trade wastewater pre-treatment device in food handling and preparation processes.

It's designed to collect grease and oily wastes by flotation and coagulation and to settle solid material as sludge. This prevents these materials from discharging into the wastewater system and causing blockages.

The effectiveness of a grease arrestor is dependent on good housekeeping practices and frequent clean out and maintenance.

Figure 1: Longitudinal cross-section of a typical grease arrestor

The water level during normal operation is in line with the bottom invert level of the outlet pipe (the dotted line).

Visit our typical drawings section to view this and other typical drawings for trade waste.

Maintenance

Pump out

Your grease arrestor is not a bottomless pit and the grease and sludge captured must be pumped out regularly to ensure it keeps working effectively. Proper maintenance of the grease arrestor, including regular pump out, is your responsibility and is a condition of your trade waste permit.

A grease arrestor requires pumping when:

- The total amount of floating and settled solids exceeds 30% of the effective depth of the grease arrestor

- The wastewater quality exceeds our acceptance criteria for oil and grease or suspended solids on two consecutive grab samples taken 24 hours apart or a representative flow proportional composite sample

- There are gross solids or oil and grease visible in the trade waste sample point downstream of the grease arrestor

Pump out of grease arrestors and disposal of the captured sludge, although a pre-condition of the trade waste service, isn't provided as part of the service. You need to make separate arrangements for grease arrestor pump out through a licensed liquid waste contractor. The contractor will charge you for the cleaning of the grease arrestor and transportation of the waste to an appropriate waste treatment and disposal facility. They may also on-charge the costs of final treatment and disposal of this sludge. Alternatively, the treatment facility operator may invoice treatment and disposal costs separately.

Pump out frequency

We set the frequency of cleaning the grease arrestor and pumping out grease and sludge and it typically depends on the type and size of the grease arrestor and the nature and volume of the wastewater produced by your operation.

The pump-out frequency of new connections is determined when we assess your application to discharge trade waste.

You must adhere to the pump-out frequency nominated for your grease arrestor. If you don't have a frequency set, or if the volume or nature of your wastewater changes as your business evolves, then you must contact us to request a reassessment.

Pump out reassessment

You may request for us to undertake a reassessment of your grease arrestor pump out frequency. This will involve a series of inspections to determine the point at which the grease arrestor is deemed to have failed, by discharging wastewater that exceeds our acceptance criteria. A service fee for a reassessment applies.

General maintenance

To assist the liquid waste contractor, the area on and around the grease arrestor is to be kept clean and tidy. Access must be maintained at all times for both your liquid waste contractor and our personnel.

Covers are to be regularly checked for damage or deterioration and where applicable, must be greased at least once a year to ensure a gas tight seal is maintained between the covers and the frame. The covers must sit flush with the frame.

Cleaning

A liquid waste contractor licensed by the Department of Environment Regulation is the only person who can clean a grease arrestor. We recommend you use a FOGMan liquid waste contractor. They have additionally agreed to comply with our Code of Practice to pump out your grease arrestor and report to us on your behalf.

It's the responsibility of the trade waste permit holder to ensure that a hose tap with adequate backflow prevention is available adjacent to the grease arrestor.

Record keeping

It's the responsibility of the owner, or operator, of the grease arrestor to maintain records of all inspections, maintenance and pump outs. Our staff may inspect these records from time to time.

Enzyme/biological products

These products are being marketed as additives to grease arrestors and claim to reduce pump out frequency. These products require prior approval. Any requests to use such products should be referred to our Trade Waste section.

Installation guidelines

Grease arrestors must be installed by licensed plumbers according to our trade waste requirements and the manufacturer’s instructions.

Sizing requirements

Find out about size requirements for a grease arrestor to ensuring the wastewater discharged meets our requirements.